SIEWERT BRIDGE ™ SMART CAD/CAM PROSTHETIC SOLUTION ON IMPLANTS

DENTAL LABORATORIES APPRECIATE THE EFFICIENT PRODUCTION

PEEK is faster and cheaper to process compared to titanium or CrCo. The CAD / CAM workflow enables efficient production while maintaining the quality of the work. The SIEWERT BRIDGE concept is unique as it allows extensive control by creating an exact PMMA copy and possible errors are identified before the final work is finished. With the appropriate dimensioning of the PEEK framework cantilevers up to 1,5 molars are viable. The physical material properties avert fractures and protect the distal implant.

START TOMORROW, YOUR DENTIST WILL BE THRILLED

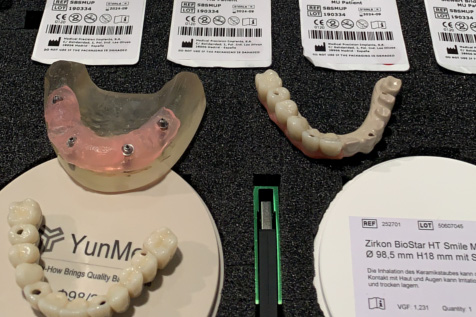

The starting components for the entry into the SIEWERT BRIDGE concept are:

Scan ScanBodies for laboratory or intraoral scanning.

STL archives of the scanbodies for the exocad implant library.

USB stick with video manuals for easy-to-understand step-by-step instructions.

The SIEWERT BRIDGE SCREW, the key to many of the advantages. As a laboratory screw and as a surface-treated sterile patient screw.

The unfilled PEEK disc (20mm, 98.5, with step) as the validated carrier material of the system.

The unfilled PEEK guarantees biocompatibility and the required material quality.

1,20 Hex screw driver.

THE INTELLIGENT MATERIAL

PEEK is not just an alternative to metallic materials, it is clearly the better solution. Correctly dimensioned, PEEK is more resistant than metals due to its modulus of elasticity in combination with its breaking strength. What is unique about the SIEWERT BRIDGE is that no metal inserts are necessary in the area of the screw. Glued or pressed metal sleeves weaken the PEEK bridge structure and bring disadvantages.

© 2023 SIEWERT BRIDGE